highlights

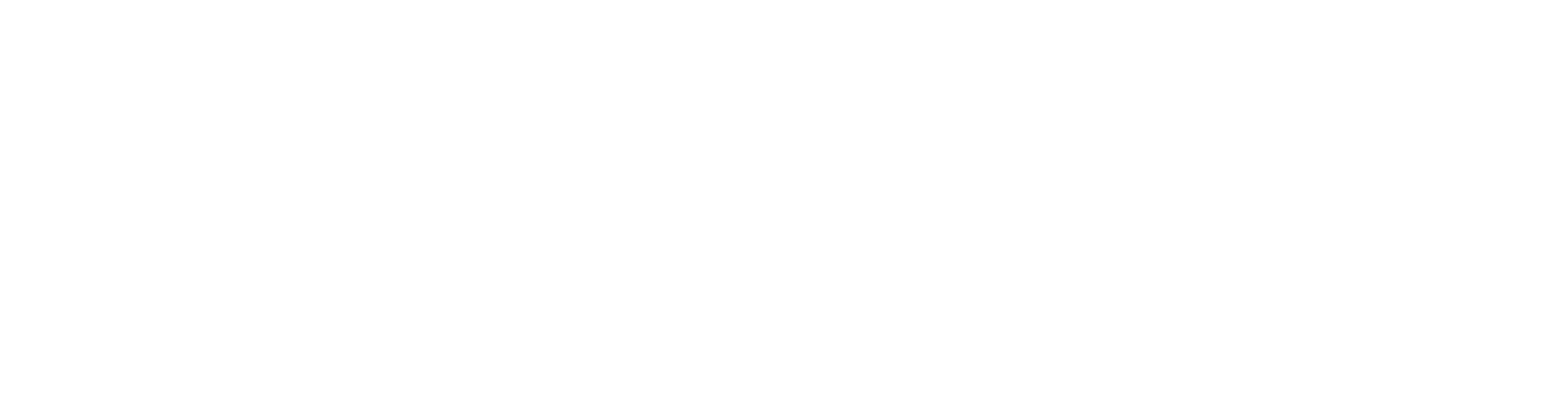

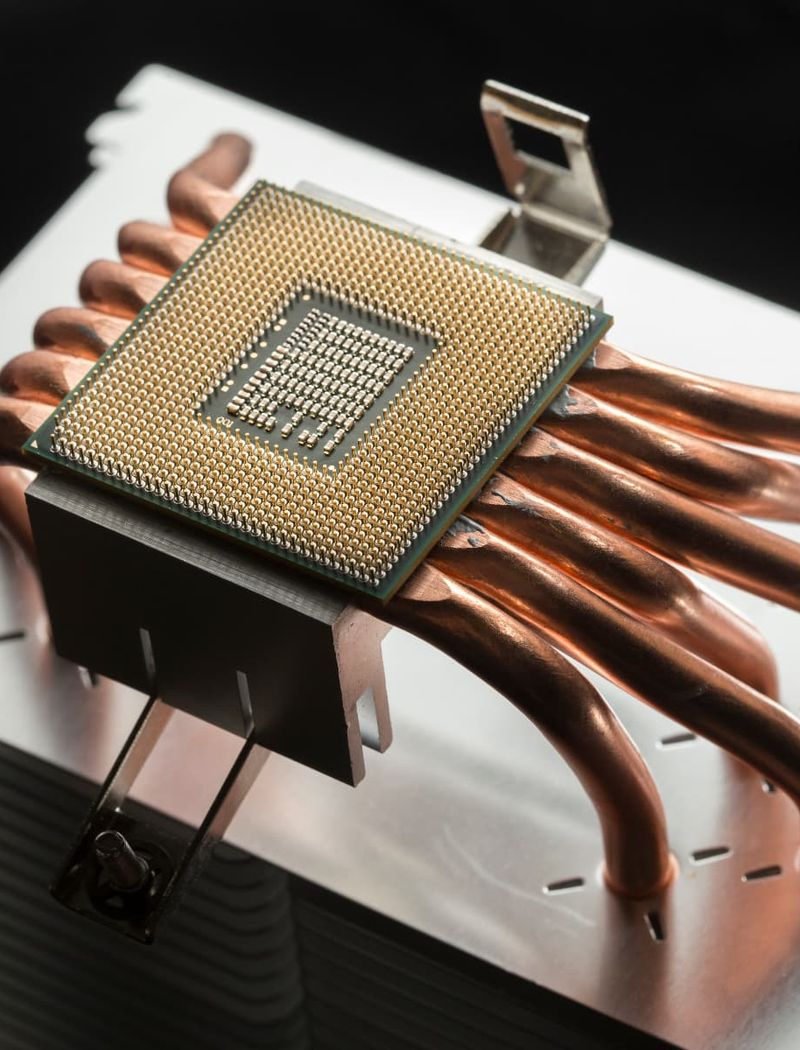

- vacuum chamber / feed-through design

- vacuum & cryo loading / load lock systems

- vacuum system (LEM) modelling

- cooling/heating systems that are (U)HV compatible

vacuum-compitable materials.

SEM, TEM and EUV, along with advanced (cryo)cooling and other high-tech applications, work with (ultra-high) vacuum. We apply our broad, thermal and mechatronics expertise for developing systems with (ultra-high) vacuums. We design effective seals and feed-throughs, have extensive knowledge of outgassing and vacuum-compatible materials, and can use cleanroom facilities for clean system assembly. With our dedicated test equipment, we accelerate the development of (ultra-)high vacuum solutions. Using our in-house Simulink LEM Toolbox development lets us simulate vacuum systems and predict their dynamic behavior.

"a broad track record."

“Cryogenics and vacuum technology go hand in hand. In cryogenics a vacuum is used to minimize parasitic heat load to the cooler so it is crucial for operating the system. As a specialist in cryogenics, we have a broad track record in designing and realizing vacuum systems. From vacuum (thermal) feed-throughs, RGA and vacuum safety systems to material vacuum compatibility and cryopumps. We’ve got you covered!”

.jpg)

.jpg)

.jpg)

.4819397517266713280.jpg)

.jpg)