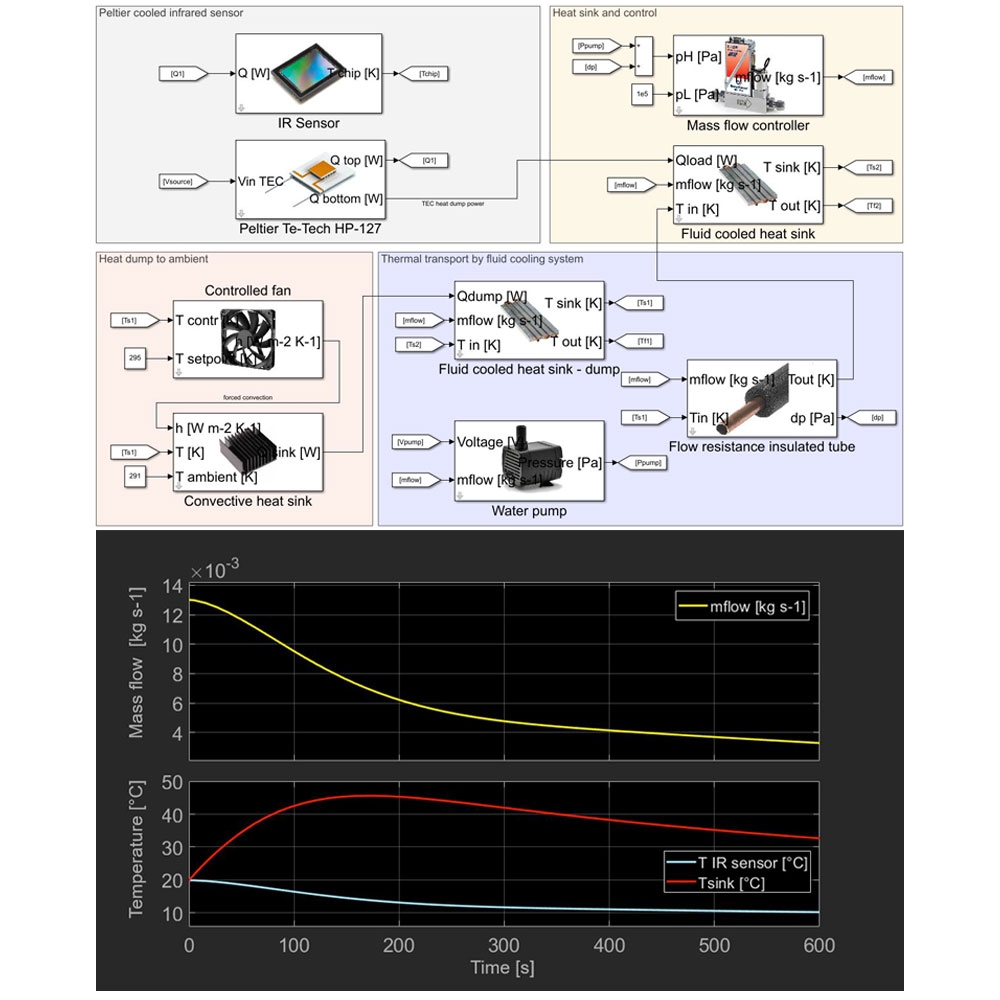

a basic LEM example using our toolbox.

This simple LEM model example illustrates our solving method and approach. Although very basic, the model already shows the high level of insight you can gain into complex systems with this approach. The model combines a thermo-electric (Peltier) cooling part with a fluidic/thermal transport sub-system and an ambient, forced convection heat dump. Among other things, this model can, determine the temperature of the IR sensor and its cool-down time, the required water flow through the heat transport system, and the resulting fluidic pressure drop over the transport lines, which may help in determining the required fluidic pump specifications.

highlights

- fast model realization using over 200 existing LEM model blocks

- predict full (real-time) dynamic behavior of large and complex systems and processes that may consist of many different parts

- model block integration of COTS performance specifications and data, giving even more accurate results

- combination of thermal, fluidic and vacuum system parts

finding potential bottle-necks.

Modelling a complex system using the LEM method provides a lot of insight into a system’s behavior, potential bottlenecks and crucial parameters. Even before a system is realized, we can predict the impact of certain design choices or the use of specific (COTS) parts, based on their product specifications which we integrate into our models. This approach makes it easy to compare different design concepts or do parameter sweeps, finding sweet spots and optimizing a system. Models are usually validated with proof-of-principle setups. These model types are also often used to find explanations for any typical, often unwanted, behavior of existing systems, so that root causes may be found and resolved.

a few LEM block examples from our Toolbox.

This example offers an impression of the variety of model blocks implemented in our LEM Toolbox library. The blocks contain the physics to model the often very specific phenomena or processes, and are combined with COTS data from suppliers to yield even more accurate simulation results.

"the ability to predict."

“What makes us unique is the ability to predict, often very complex, systems, verifying model results using our hands-on experience with many different thermal systems and processes. It’s really nice to start from an idea, create different concepts, model their behavior, and then finally realize these into actual concrete systems. Verifying that your model predictions were correct, is extremely satisfying!”

.4819397517266713280.jpg)

.jpg)

.jpg)

.jpg)

.jpg)