highlights

• thermodynamic simulation and system engineering for temperature control

• mechatronics, electronics and software for high accuracy positioning systems

• a fully functioning glass printer

• research and demonstration function

• accurate platform design

• meticulous temperature control

improved accuracy.

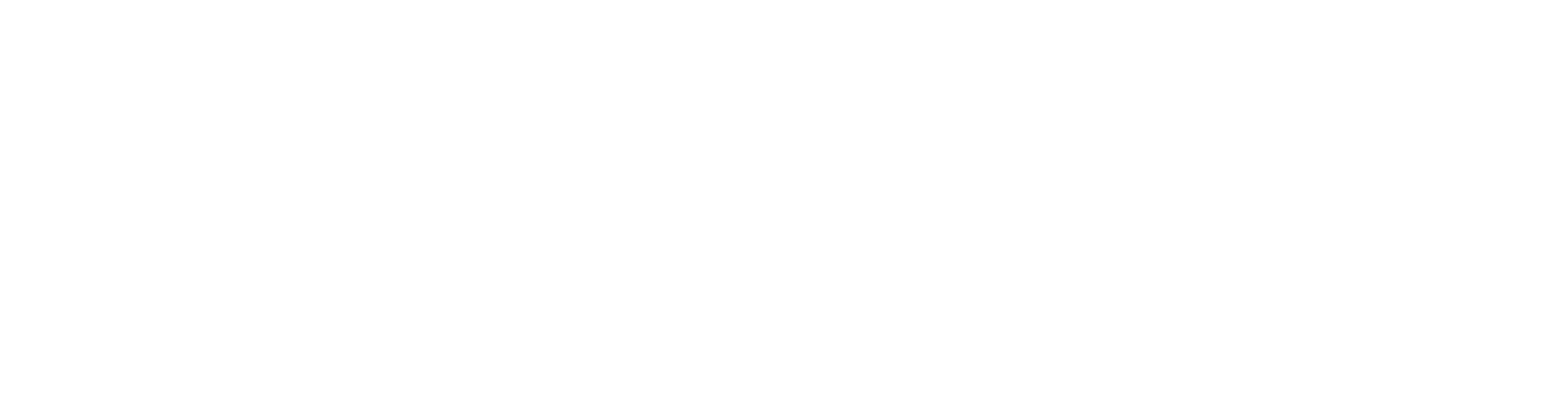

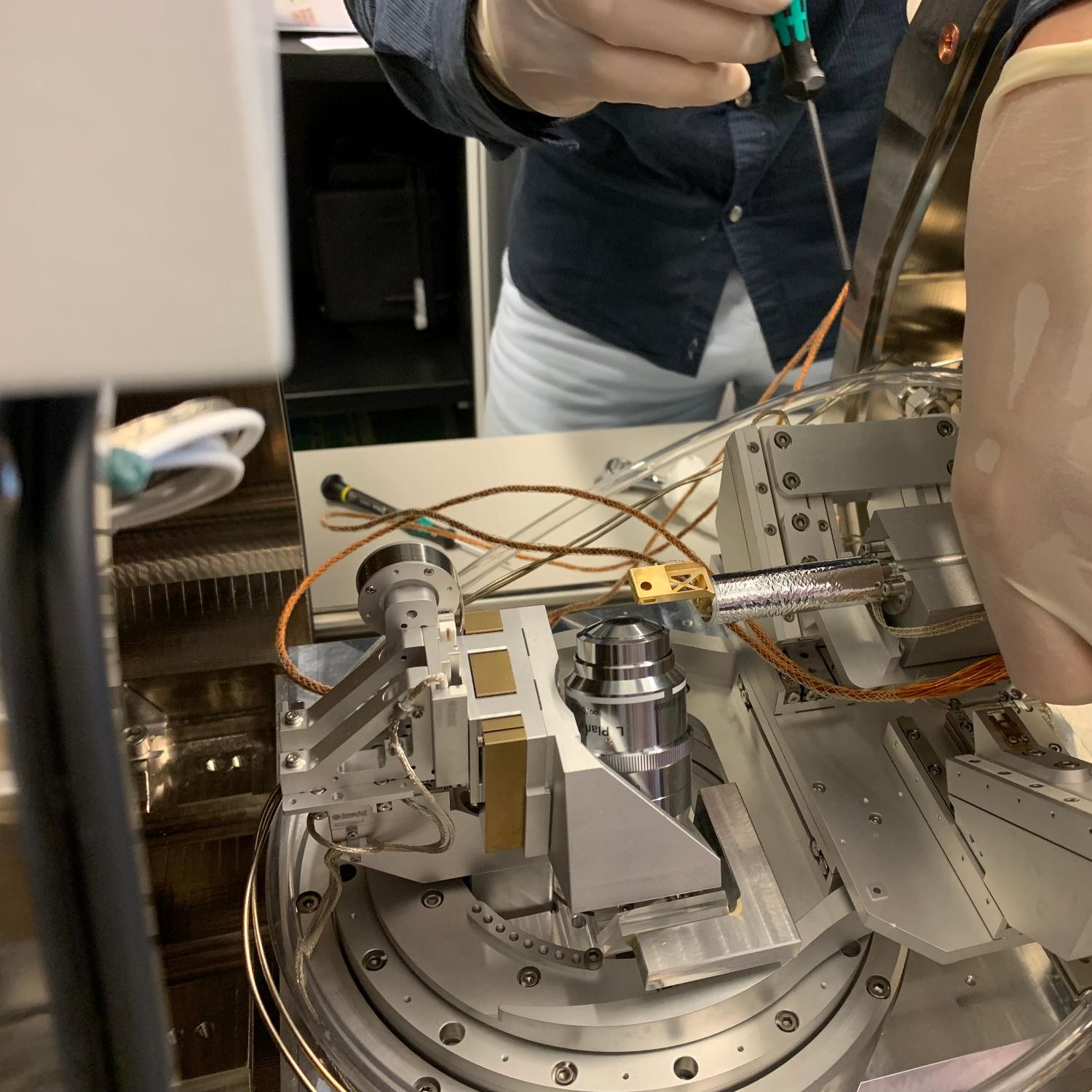

The glass printer we designed and built consists of an oven with a fixed print head and a movable deposition platform. The print head was delivered to us. We kept as it was, although we created a smaller glass flow for more precise printing. For the rest, we changed everything around it. An important improvement was the new platform or stage, that in the original lay-out didn’t have the required accuracy. Thanks to a G-code for 3D-printing it follows an x-y-z contour beneath the flow of molten glass to create the required product. This enables the complex shapes 3D printing is known for.

By carrying out the project from specification up to installation, we provided the engineering, control software and hardware to give the platform the required < 50 micrometer level accuracy in positioning as well as movement. Built-in data monitoring enables to remain within specs during operation. It also allows for analysis of production conditions in relation to the finished products. Thus a safe, robust and accurate glass printer was created.

temperature control.

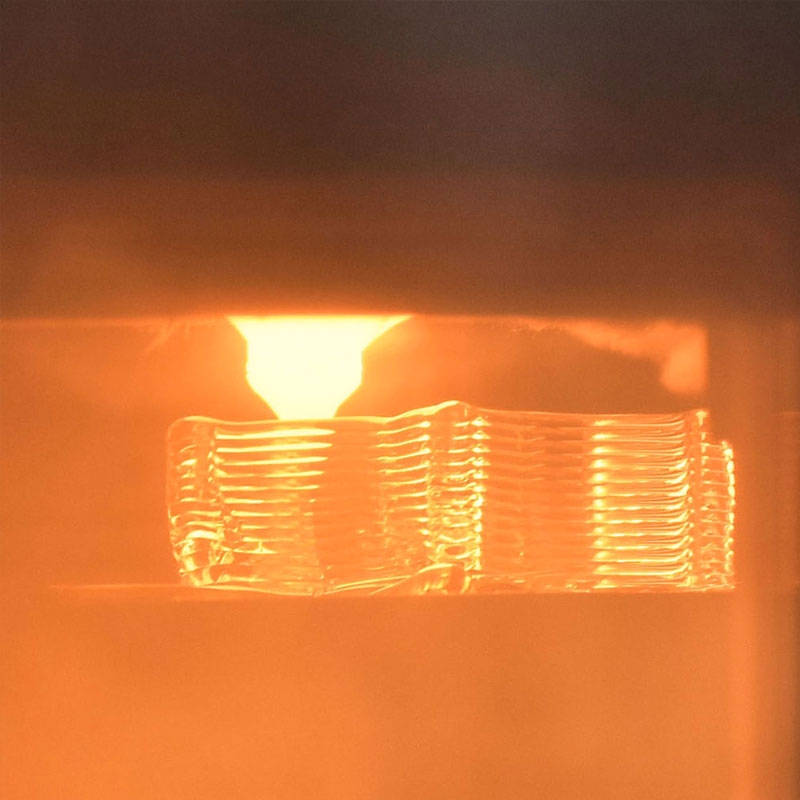

Crucial to the final result was careful temperature control. This regards the melting glass in the printhead at 1,600-1,700 ºC as well on the printing stage and the offset with regard to its surrounding area at around 700 ºC. The solidification process should proceed slowly to prevent material tensions. Furthermore, the atmosphere was made oxygen-free to keep out oxygen induced material degradation. We therefore had to develop advanced control and safety strategies. Thermal system simulations served to underpin the design choices in hardware and software. In hardware this involves materials and in the software it is about possible compensations.

"the first in the world to achieve this."

When technologies do not yet exist, we are among the few parties that can succeed in realising them. This 3D glass printing project was a typical multidisciplinary Demcon feat, involving our competencies in mechatronics, thermodynamics, materials science and production. Together we have met the specifications for temperature, mechanical stability and accuracy. Especially our ability to find solutions for handling extreme temperatures is something to be proud of.