highlights

• (thermal) design analyses and optimization

• design for production

• space qualification with (industrial) partners

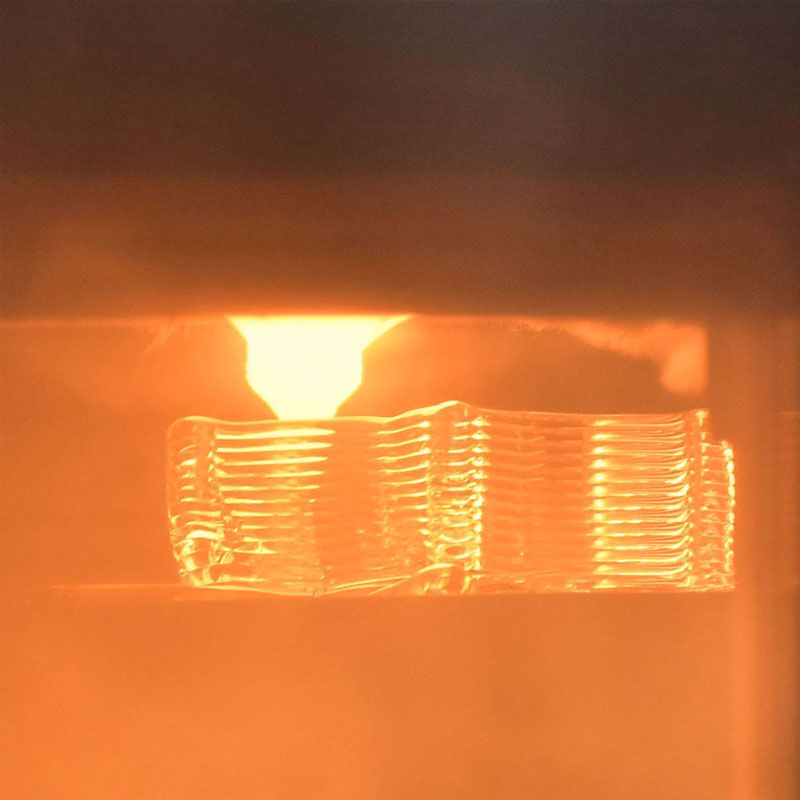

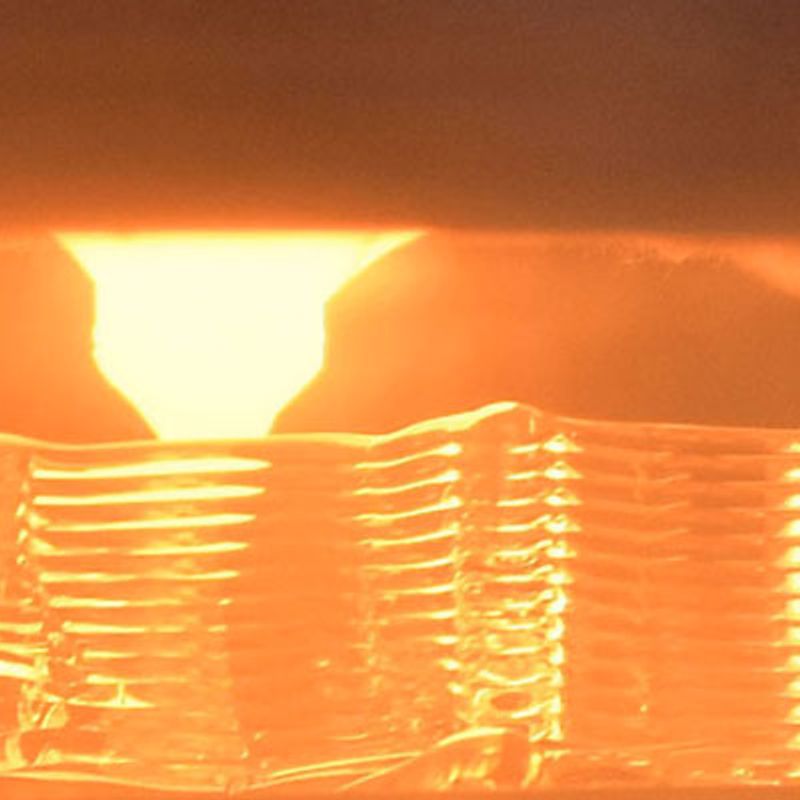

dumping heat in space.

The only way for space satellites to reject heat tot the environment in space is through radiation. For low power (<20 Watt) satellites a ‘simple’ passive radiator can be sufficient, but higher powers require a more advanced thermal control.

CubeSats.

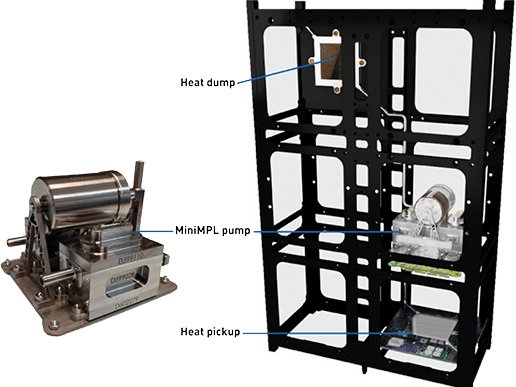

The sizes of small satellites (also known as nanosatellites) follow the CubeSat standard, which defines the outer dimensions of the satellite within multiple cubical units (U). 1U is equivalent to dimensions of 10x10x10cm. A typical size that can accommodate small technology payloads is a 3-unit CubeSat with dimensions of 10x10x30cm. A thermal control system becomes relevant for 3U CubeSats with large deployable solar panels, or 8U without deployable solar panels.

thermal control for CubeSats and microsatellites.

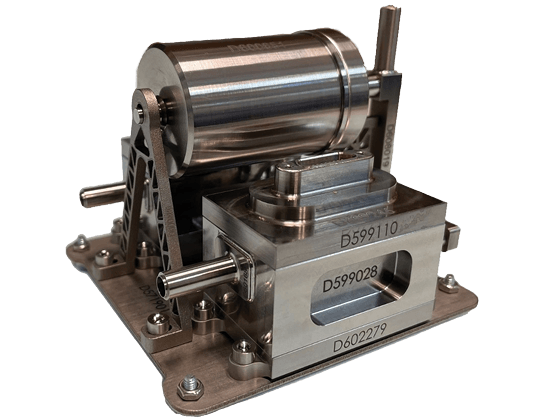

This compact thermal control system is specifically developed for small satellites such as CubeSats and microsatellites under 100 kg. Despite its minimal size—less than 1U in volume and approximately 1 kg in mass—it delivers exceptional performance, removing 40 to 100 watts of heat using only 2 to 5 watts of electrical input power. This allows satellite operators to manage high thermal loads without compromising limited onboard power budgets or system volume.

Thanks to its efficient design, the system is ideal for missions where thermal control is critical but available space and power are severely limited. It enables stable operating conditions even in the most compact platforms, supporting advanced payloads and extending mission lifetime.

"space, the final frontier?"

Dumping heat into space might seem an easy task since space is extremely cold, right? In reality this isn’t (always) the case. Besides being very cold, space can also be very hot. Moving heat away from dissipative devices inside space satellites towards space radiators is a challenging but really interesting task. It’s great to work with partners like ESA, NLR and ISIS Space to solve these issues.