highlights

• Turnkey solution

Fully automated system with minimal installation demands.

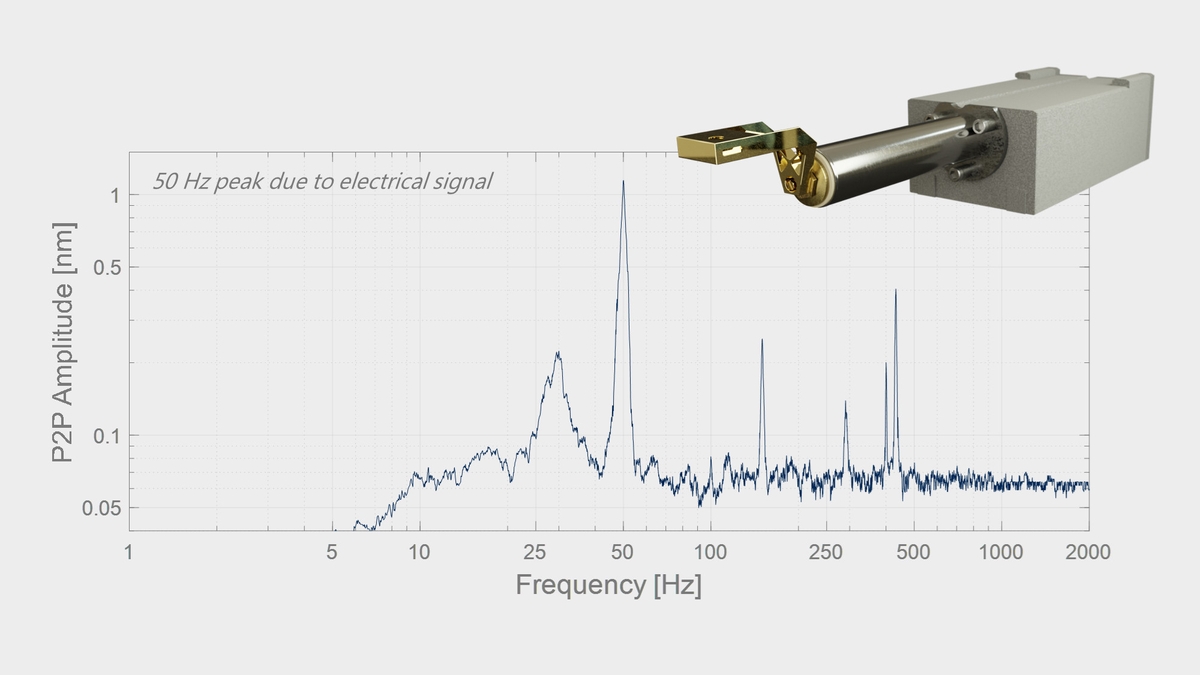

• Vibrations levels < 1 nm p2p with < 3 nm/min drift

Ultra-low vibration and thermal drift levels.

• Wide temperature range: 100 – 473 K ± 10 mK

Variable temperature control across the entire range.

• Cryogen-free system

No LN2, no cryogen handling, no frost, no hassle.

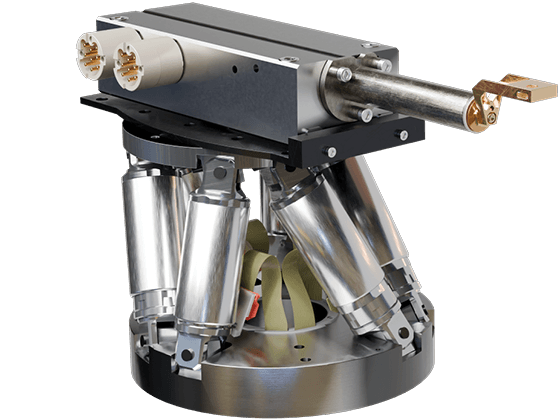

• Move your sample in six-degrees-of-freedom

Cryocooler allows for movement in 6 DOF.

research.

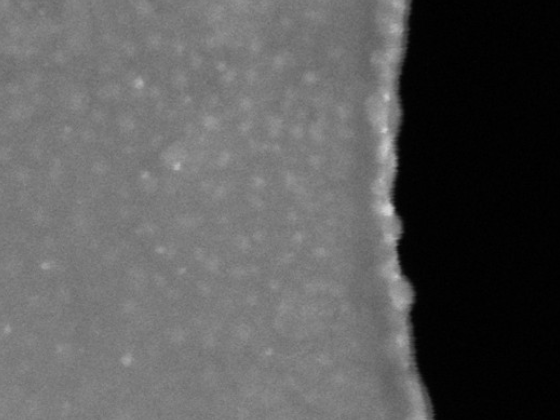

Understanding the mechanisms behind cell function and disease is a

central goal in life sciences research. Increasingly, scientists are turning

to cryogenic techniques to study proteins, viruses, and bacteria at

ultra-low temperatures. This growing demand has driven the rise of

cryo-electron microscopy (cryo-EM), where stability and precision

are paramount.

The field of application has now been extended to X-Ray Microscopy (XRM), Transmission Electron Microscopy (TEM) and Laser Scanning Microscopy (LSM).

compact, powerful, and precise.

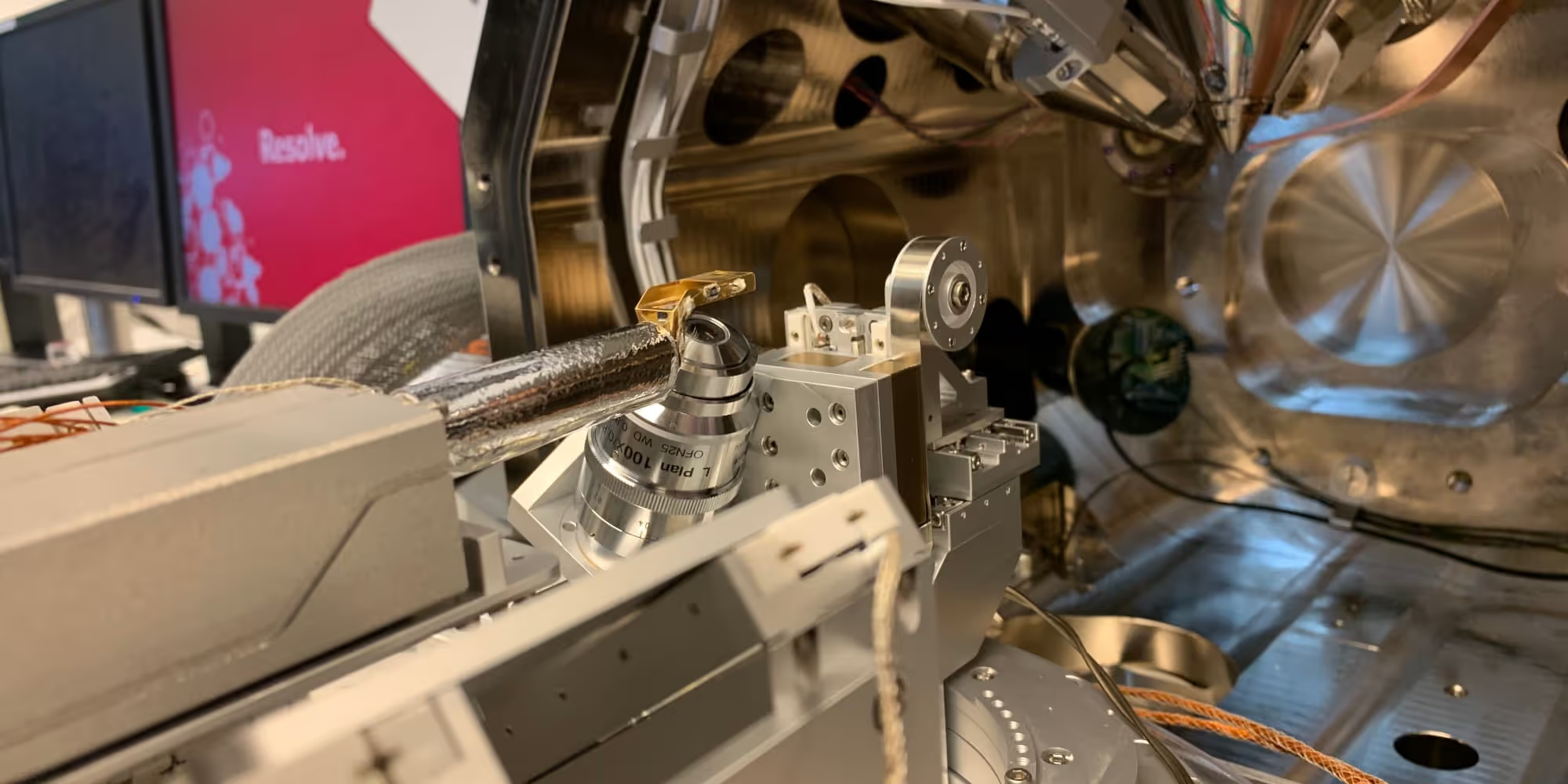

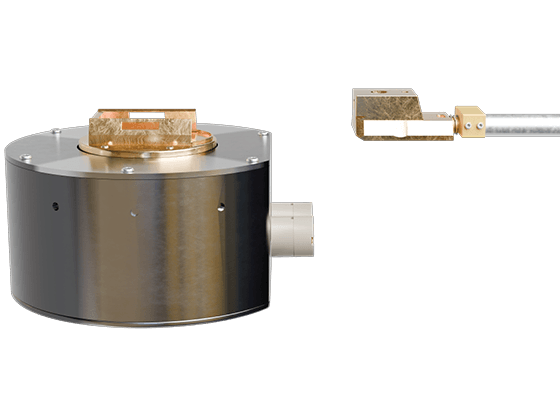

Measuring just 16 centimeters, our cryocooler maintains sample temperatures

between -150°C and nearly -200°C. Despite its small size, it supports

full six-degree-of-freedom (6 DOF) movement, allowing researchers to study

samples from any angle. The cooler connects to a tube no wider than a little

finger, housing a microfluidic chip that enables nitrogen gas expansion for

efficient cooling. This design ensures that only the sample area is cooled,

while surrounding hardware remains at room temperature—minimizing

thermal stress and maximizing integration flexibility.

ultra-Low Vibration and Thermal

Drift.

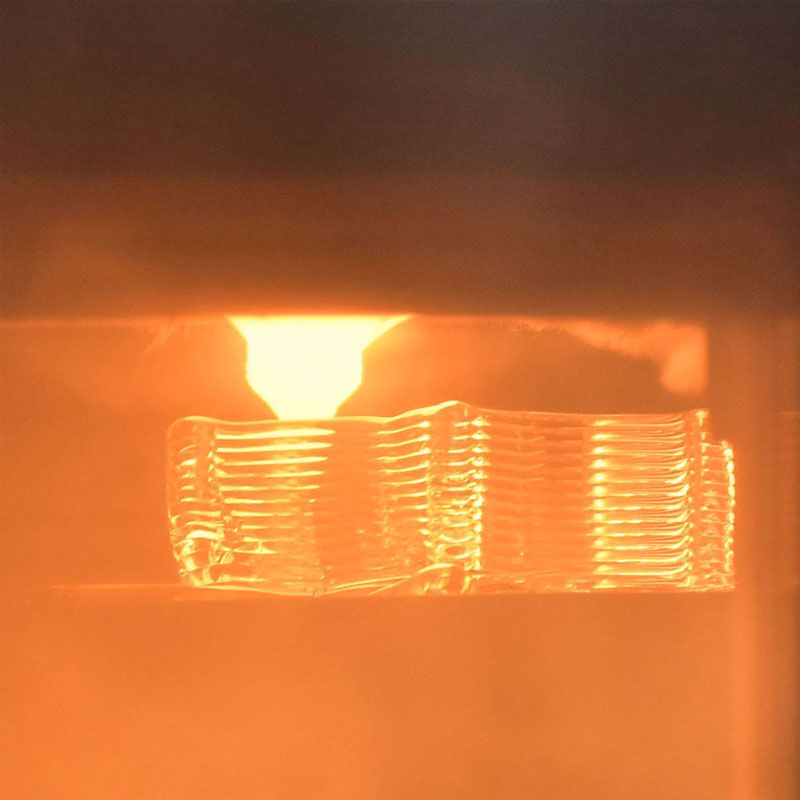

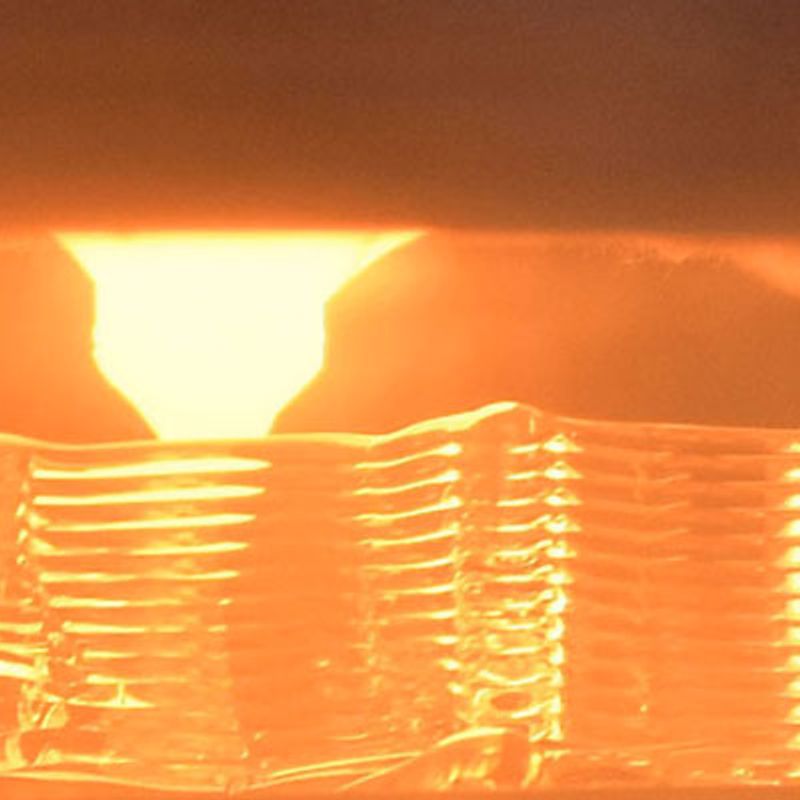

Our cryocooler achieves vibration levels below 1 nanometer peak-to-peak,

with ongoing development targeting an impressive 0.1 nm p2p.

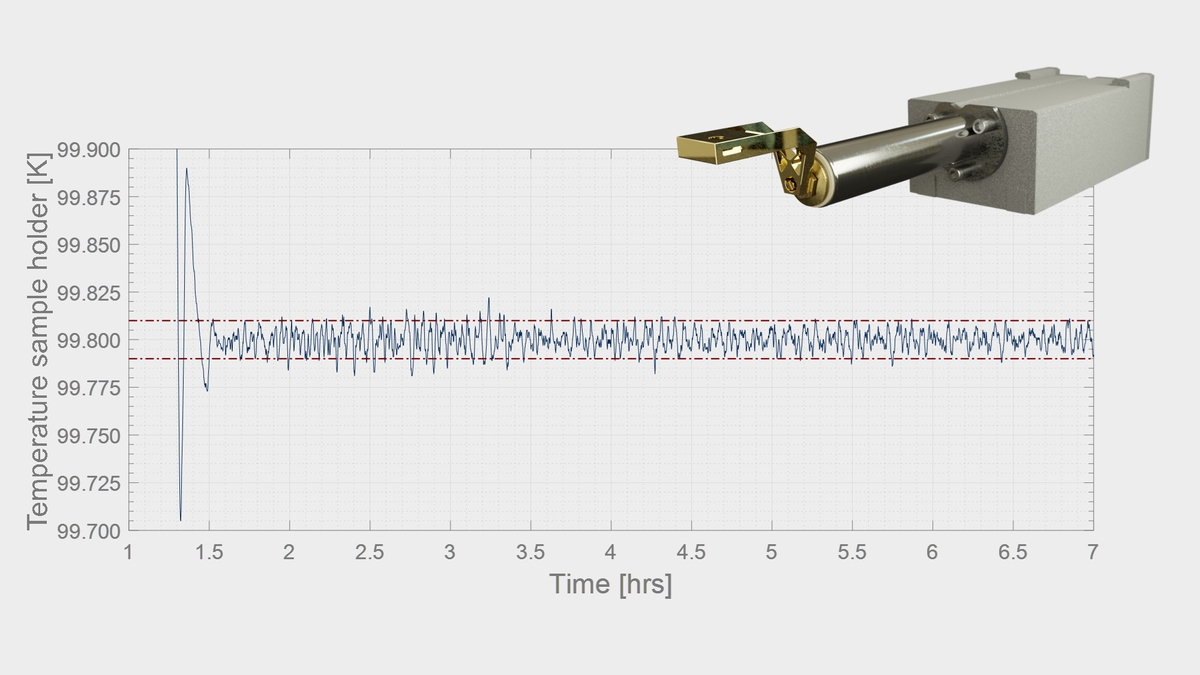

Thermal drift is kept under 3 nanometers per minute, thanks to precise

temperature control with an accuracy better than ±10 milliKelvin across

a wide range (100–473 K). This stability is critical for advanced imaging

techniques such as FIB/SEM, TEM, XRM, and LSM.

seamless Integration and Operation.

The system is fully automated and cryogen-free—no liquid nitrogen, no

frost, no hassle. It operates using standard N₂ 5.0 gas cylinders, with a single

bottle lasting up to a week of continuous use. The cryocooler connects to any

off-the-shelf translation stage via M3 screws and integrates effortlessly with

your microscope setup. Control is simple, either via a dedicated module or

remotely through USB.

Extreme stable temperatur

Translation-stage interface is at room temperature.

Controllable sample temperature from 300 down to 100 Kelvin.

High temperature stability ±10 mK.

Extreme stable position

Low vibration level ~ 1 nm p2p.

Low drift levels of <3 nm min-1.

Performance testing was done using a TF Helios FIB/SEM/FM with the cryocooler mounted on a 5 DOF manipulation stage.

"when rock solid cryocooling is crucial."

Creating a cryocooler that is compatible with the extreme requirements of a scanning electron microscope is a highly challenging assignment. This is due not least because the extremely low levels of thermal drift and vibrations can only be verified by the microscope itself. Concept choices had to be made, based purely on simulations and experience. It’s really cool to see that our predictions and implementations were correct.