highlights

• (thermal) architecture and design

• fully-controlled thermal conditions

• fully-controlled humidity conditions

• extreme high temperature stability for dew point control

rapid freezing of preparations for better microscopy.

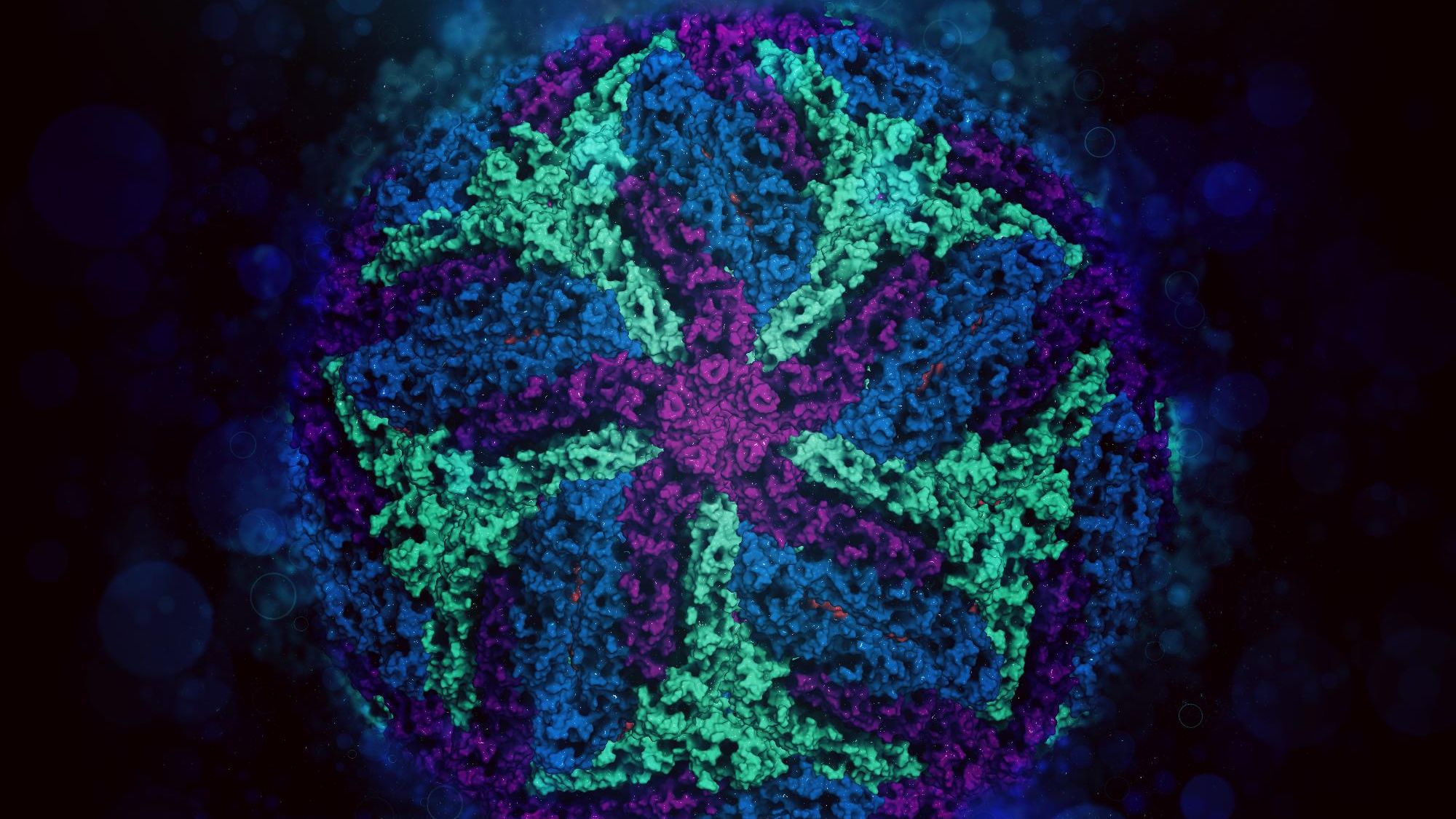

Scientific research into the causes of, and possible treatments for, various diseases focuses partly on the role that proteins play in the disease processes. Proteins (the building blocks of life) are being studied with electron-microscopy (EM). This takes place at very low (cryogenic) temperatures (cryo-EM), and for this the proteins are first frozen so as to obtain a sharp image. Proteins must be frozen extremely fast, in a process known as vitrification, to obtain the best-quality samples/preparations. The result is a new product, the VitroJet, whose 90% yield provides better-quality preparations.

See also www.cryosol-world.com.

the more stable, the better.

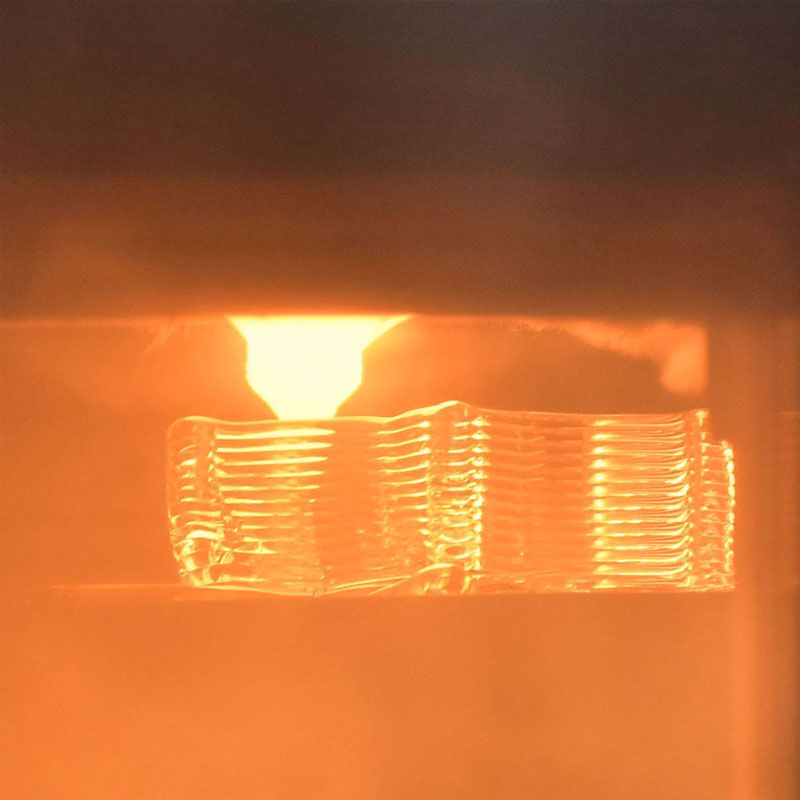

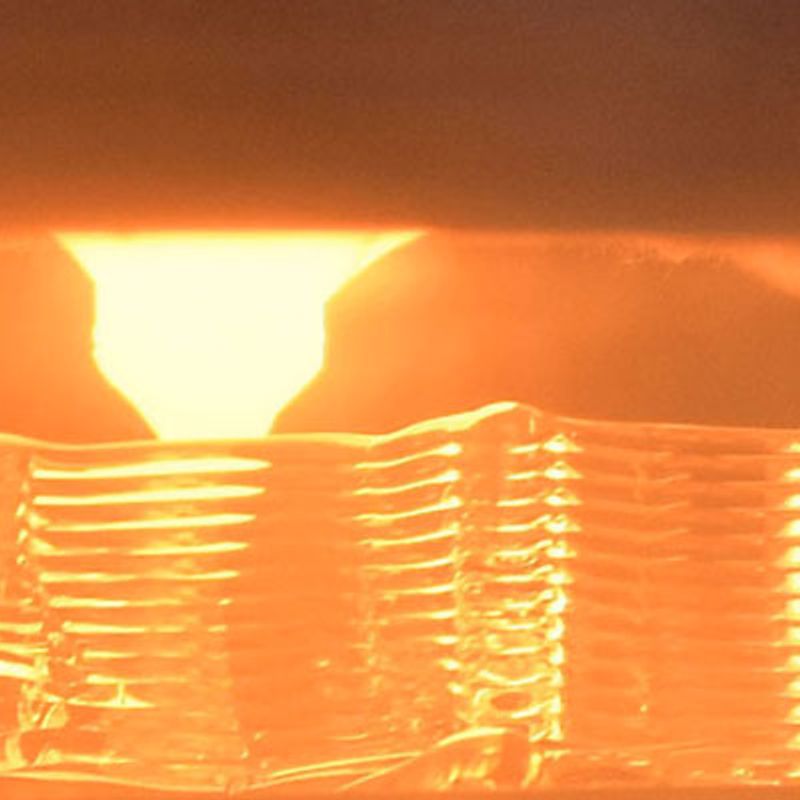

When preparing a sample for vitrification, it is extremely important that the sample doesn’t evaporate instantly or become contaminated through water deposition. That’s why sample conditioning of both temperature and humidity is so important during the vitrification process. For this purpose we designed, modeled and realized a sample environment that would comply with these requirements.

"from extreme challenge to product."

Realizing a first prototype that can achieve the required, accurately- controlled thermal and humidity conditions is already a huge challenge, but making sure the design is suitable for reproducible series production is an even bigger one. We keep this in mind right from the start of the development process, not only by using our technical expertises, but also our (thermal systems) project management experience in overseeing the full development process. This development is a typical example of a multidisciplinary Demcon achievement, where from our side we have built the bridge from extreme challenge to product.