highlights

- fluidic architecture and design

- prototyping, modelling & simulation, experiments

- CFHX/PHX pressure drop – flow-efficiency optimization

- (extreme) high pressures

- cryogenic fluids

choosing the correct layout.

When designing a thermal-fluidic system, many concept design choices can have a huge impact on the final system’s behavior. Choosing the correct parts and system (fluidic) layout can make the difference between a non-working system or one which is fully optimized with high efficiency. We are the perfect partner in realizing your dreams, with our knowledge of the fundamentals of fluid mechanics and heat transfer, in combination with our unique approach in modelling (large) thermal/fluidic systems (using our in-house LEM Toolbox), and our extensive hands-on experience in realizing these system types.

showcase.

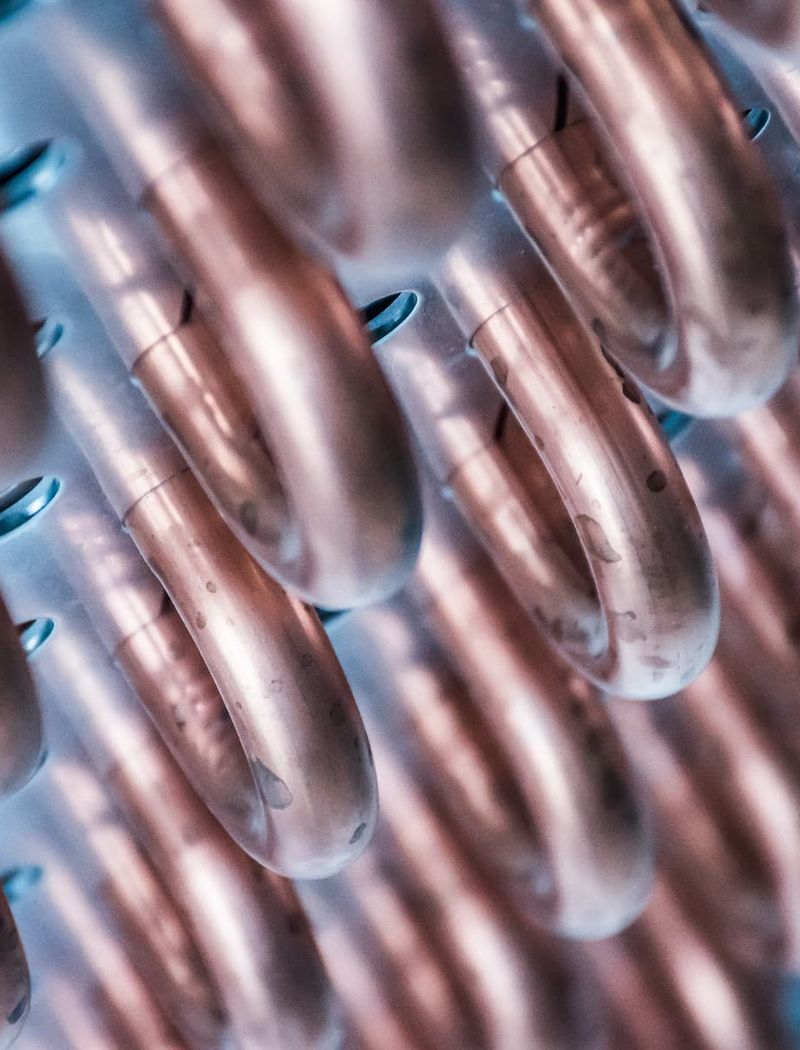

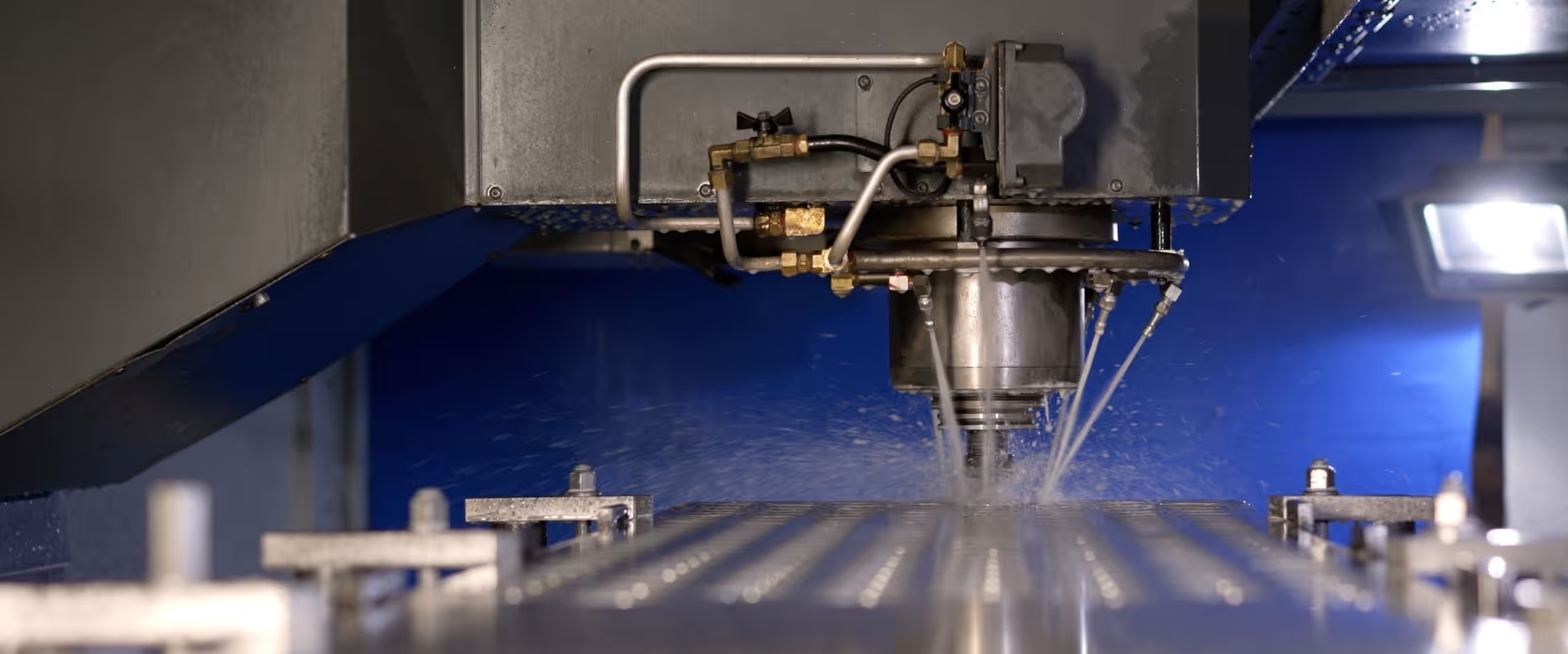

During high-speed milling, a large amount of energy is transformed to heat. This heat can negatively influence the milling process and change or degrade the used substrate material. Demcon kryoz performed a feasibility study of a cryocooler concept for cooling a high-power milling process where over 250 Watt of heat was generated. This heat had to be transported away from the substrate as quickly as possible.

"meet the specifications."

“Thermal-fluidic systems handle fluid flows in combination with thermal energy exchange. We find challenges in working with various fluids such as cryogenic fluids, liquid metal or extremely high-pressure noble gasses. We design systems in such a way that they meet the specifications of our client’s demand, for example in terms of maximum pressure drop, the required Reynolds number, heat transfer coefficients, and/or mechanical stability. And this sometimes in demanding environments like space.”