highlights

• 10 Kelvin cold-stage

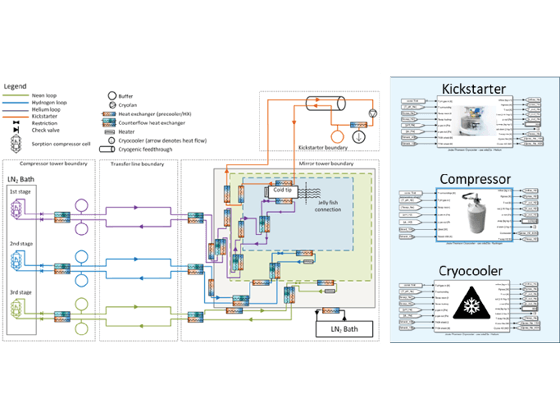

• multi-stage sorption (Ne-H2-He) compressor

• <32 nm peak to peak maximum vibration

• ultra low thermal drift

the challenge.

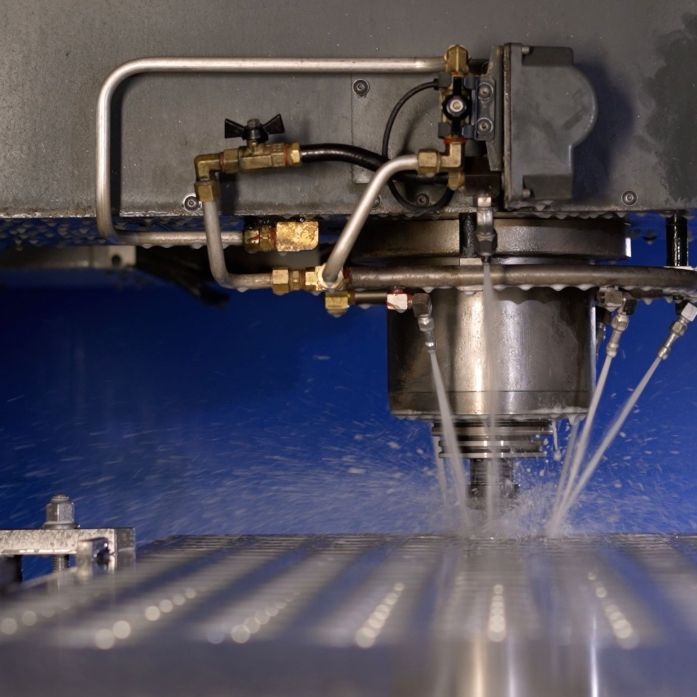

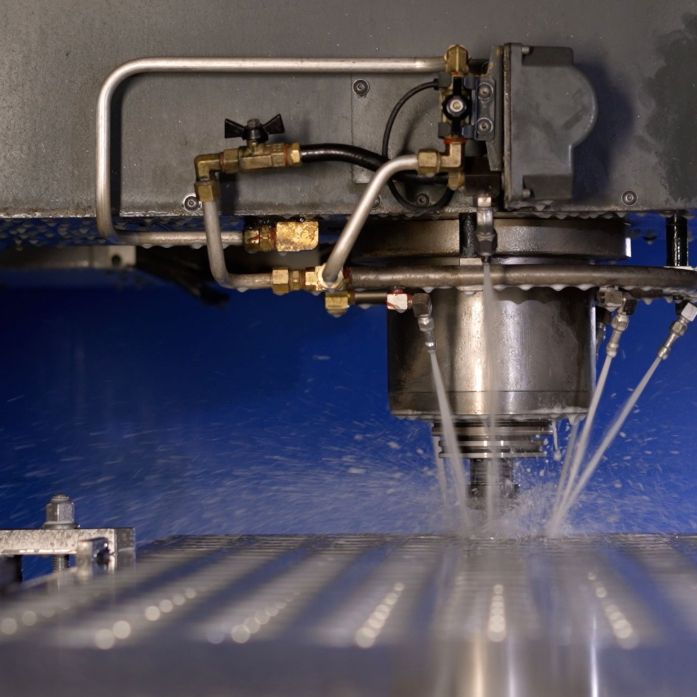

Traditional cryogenic coolers, which utilize mechanical compressors, are commonly used in (scientific) instrumentation but pose vibration challenges. These coolers often require complex attenuation systems to mitigate vibrations, making it improbable to achieve the extreme vibration requirements of the Einstein Telescope. Therefore, we propose the solution of a sorption based cryocooler to minimize the vibrations generated by the cryocooler system.

multistage sorption-based Joule-Thomson cryocooler.

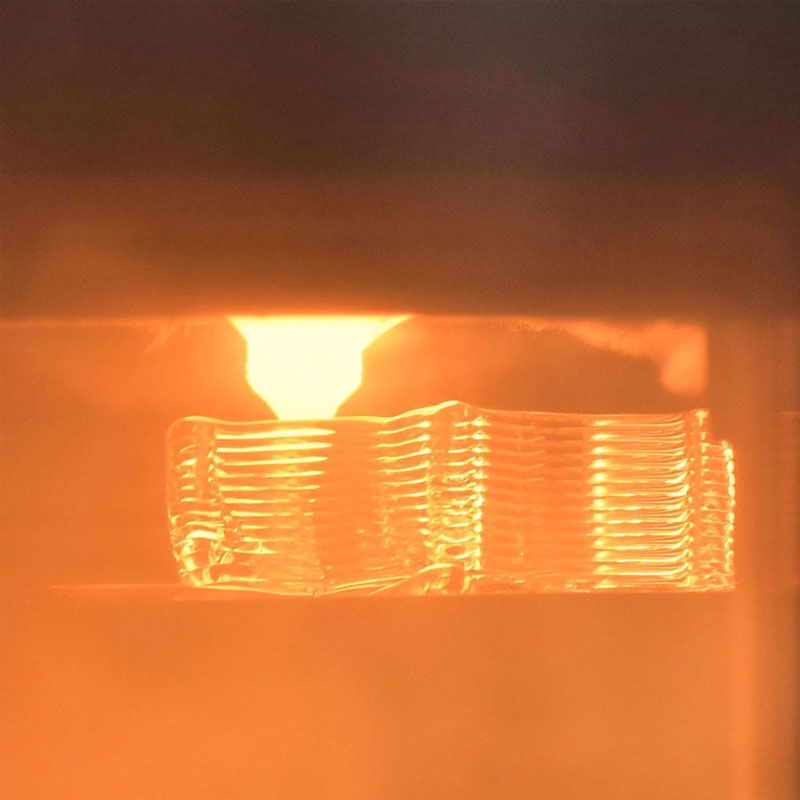

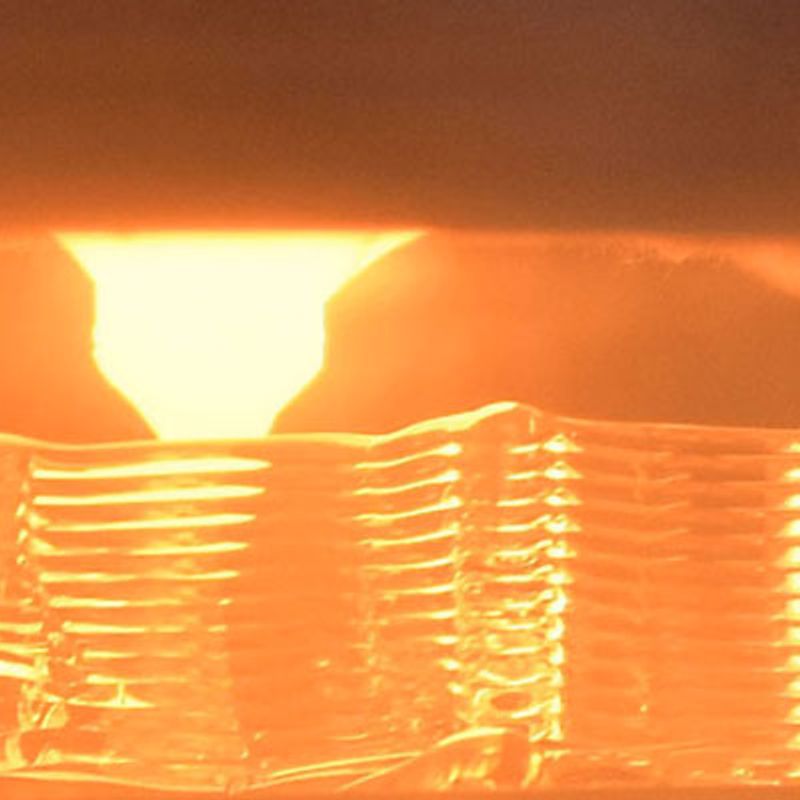

Joule-Thomson (JT) cold stages, driven by a sorption compressor, offer (virtually) vibration-free performance. These types of compressors use adsorbent materials (e.g. activated carbon), passive valves to control gas flow and gas buffers, resulting in a nearly continuous gas flow through the cold stage. An important aspect for the Einstein Telescope is that they contain no moving parts, ensuring no interference with the vibration sensitive measurements with a long, maintenance free operational lifespan.

LEM modeling.

Our in-house developed dynamic lumped element modeling approach offers an efficient approach to simulate the thermal behavior of the cryogenic multi-stage Joule-Thomson cryocooler. By representing each stage in the lumped element model, this method simplifies complex heat transfer processes into manageable thermal resistances and capacitances. This allows us to predict temperature variations across the different stages, optimize performance, and enhance cooling efficiency of the telescope mirrors. Ideal for modeling transient thermal responses, this approach aids in engineering cryogenic systems where precise temperature control is critical.

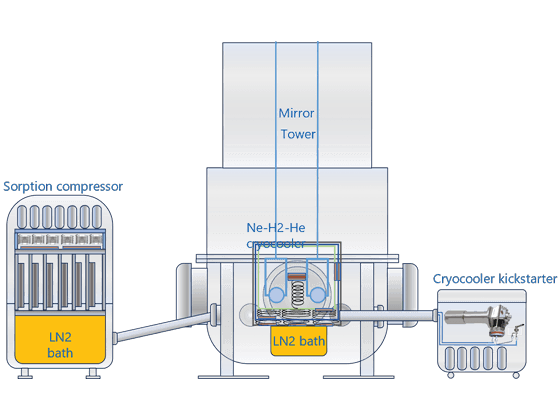

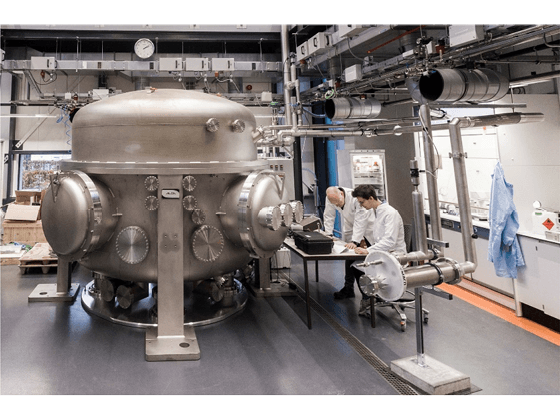

test facility Einstein

Telescope Pathfinder.

DEMCON kryoz develops and analyses the Einstein Telescope thermal system which uses sorption-based Joule-Thomson cryocoolers. The three-stage cryocooler, utilizing neon, hydrogen and helium, is able to achieve 10 Kelvin without creating mechanical vibrations. The design will be first implemented in the Einstein Telescope Pathfinder demonstrating the feasibility of the Joule-Thomson cryocooler and benchmark it against other cryogenic processes.

"large system cryocooling."

Creating a multi-stage cryocooler for a cutting edge research facility such as the Einstein Telescope is very challenging. Especially when working with a large amount of interfaces and the extreme requirements on vibrations. Using our broad experience and knowledge on JT-cryocooling, we designed, simulated and analyzed the complete cryocooling system. In the near further, we will perform verification tests in the Einstein Telescope Pathfinder at the University of Maastricht.